Aluminum engraving (with a diode)

Wednesday, February 28th, 2024

I have a running document for the optimal settings on my 20W Atomstack diode laser. It includes: wood, acrylic, fabric, glass, and even rock. However, there is a material that I’ve been meaning to try… metal.

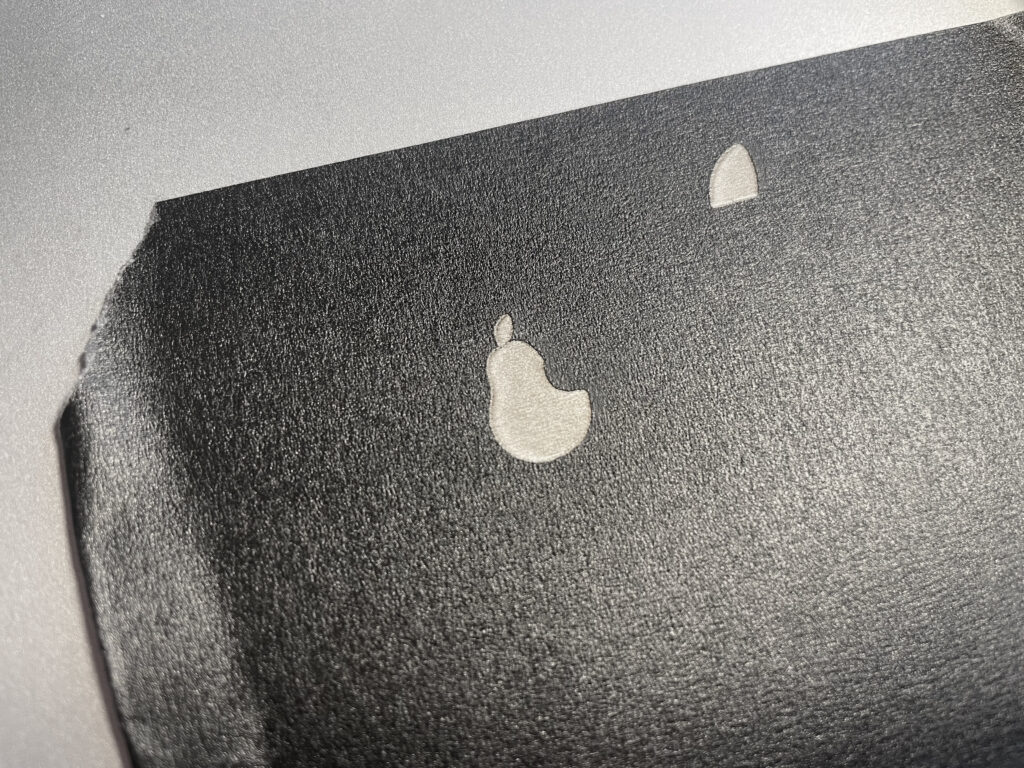

Raw aluminum would be near impossible to etch. Luckily, most of the aluminium we encounter (like your Apple laytop) is anodized. I wanted to see if it was possible to remove this layer and leave a clean etch.

TL;DR

It is possible, but quite slow: 100% power, 2mm/s, 0.05 internal gave good result when used with black masking tape.

Details

1) Prepare the surface

The first try didn’t do much. The bare aluminum is quite reflective and really good at dissipating heat. However, you can use the same trick as you do with glass – add a dark material to the surface. In this case, I just used black painters tape. I suspect that black paint would work even better, but then there would be a bunch of cleanup.

2) Go slow

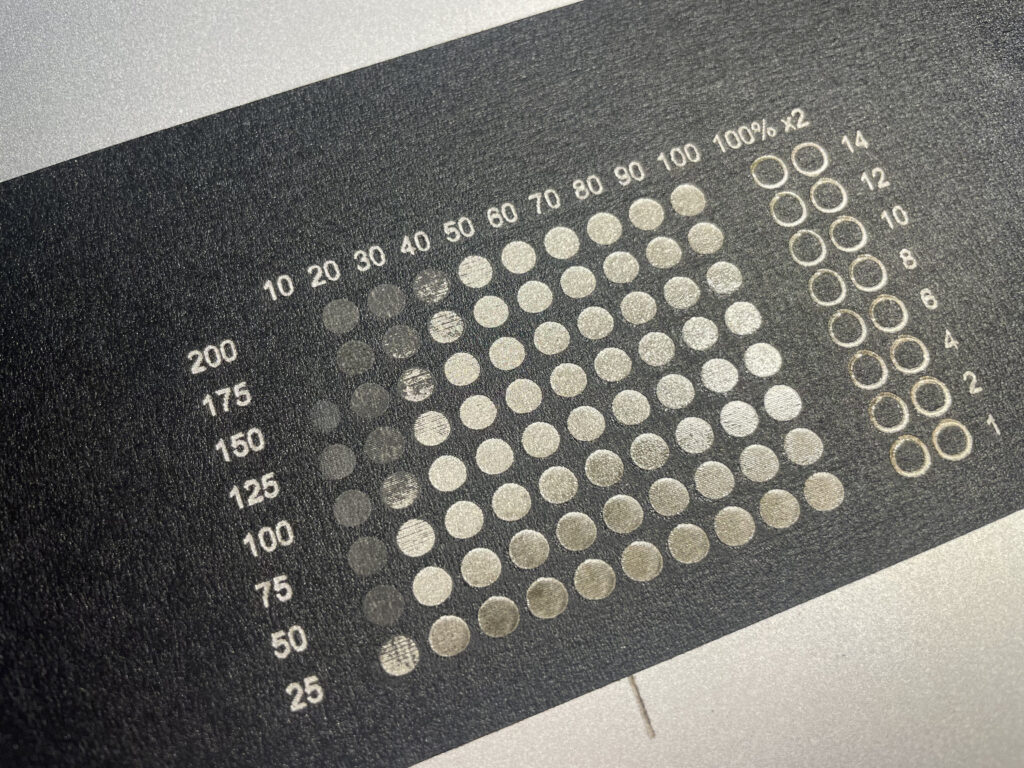

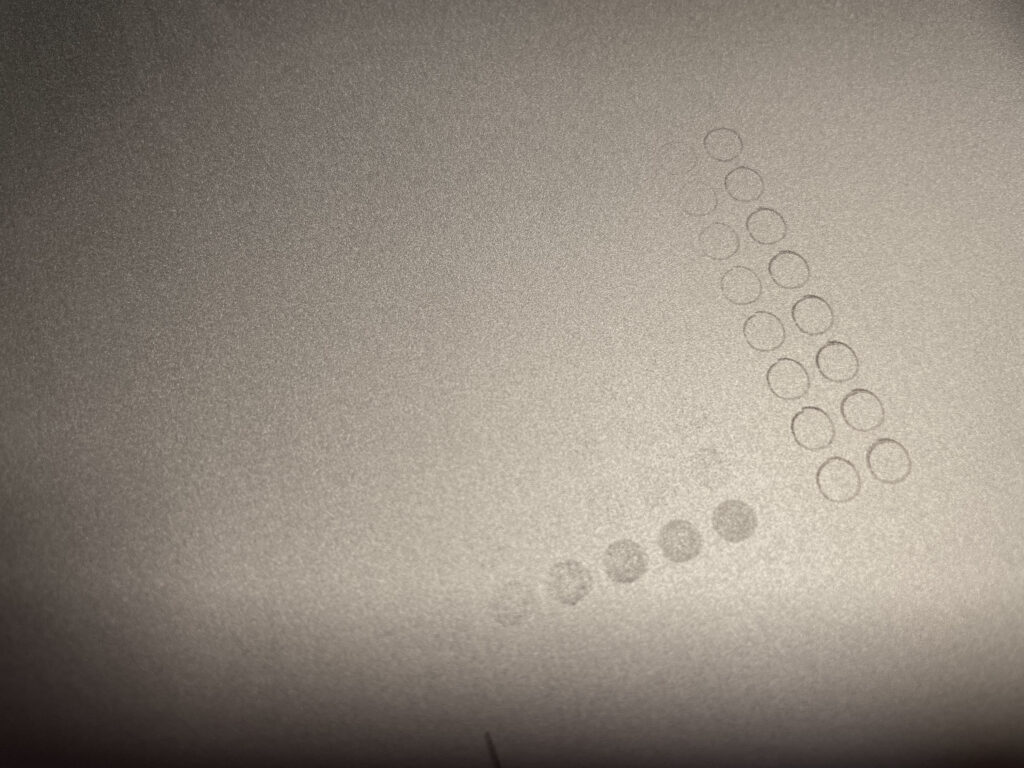

Even with the tape, you need a lot of power. A power test showed that a max of 10mm/s was a good starting point. I ended up choosing only 2mm/s. This is so slow that I ended up restarting with a smaller logo.

3) Clean up

The tape will leave residue on the aluminum. Some alcohol and a magic eraser clean things up quick.